Associated Machine Company, Inc. was founded in 1963. We have grown and developed an unparalleled reputation for Quality and Excellence in every aspect of the Manufacturing business.

Find out why so many of our customers rank us at the top of their supplier list.

Contact us Today!

Associated Machine

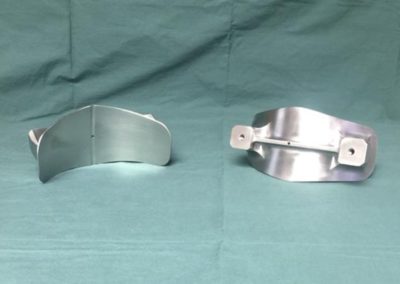

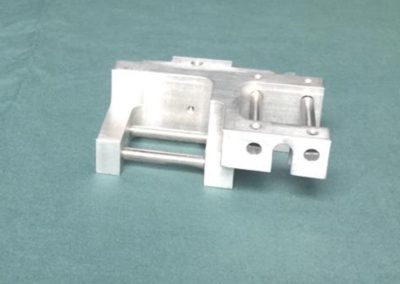

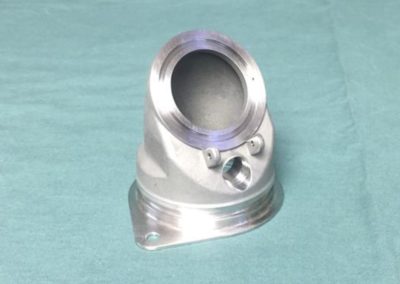

At Associated Machine, we offer complete manufacturing so that the product you receive will be complete, correct, and ready for your application.

Quality Control

CNC Lathes

CNC Mills

4th and 5th Axis

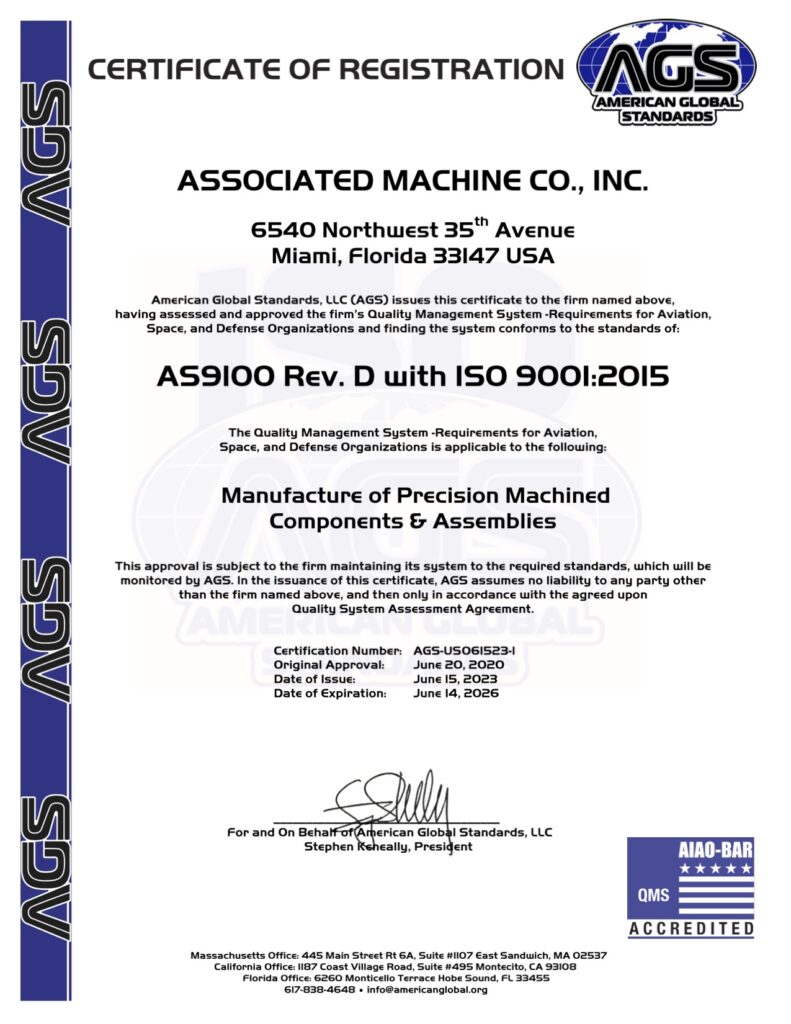

Certifications

We are a AS-9100D & ISO9001:2015 Certified Manufacturer

Whether it is a simple production part or a complex turn-key project, Associated Machine Company, Inc. has the engineering, manufacturing and technical resources to work with your company to ensure that our services help you deliver the highest quality to you and your clients each and every time!

Get In Touch

Associated Machine Co Inc.

6540 N.W 35th Avenue

Miami, Florida 33147

305-836-6163

305-691-2288

6540 N.W 35th Avenue

Miami, Florida 33147

305-836-6163

305-691-2288